Bedford's Sustainability Practices

From a product to its packaging, consumers are increasingly making purchasing decisions based on sustainable attributes.

In honor of Earth Month, we’re sharing Bedford’s approach to manufacturing more sustainable packaging and bendable solutions for the bakery, fresh produce, coffee, and medical industries.

This multilayered approach includes: 1) upcycling reclaimed packaging into other usable materials 2) reduction of packaging/raw materials and 3) researching/developing new products derived from eco-friendly resources and 4) manufacturing best practices.

1. TagBack

Consumers are asking: Are twist ties recyclable? Are produce tags recyclable?

Hearing this, Bedford started the TagBack program, which allows our customers and consumers to return packaging ties and tags back to us. Once returns arrive to our facility, they are processed through in-house equipment and upcycled into other usable materials. Some examples of how materials get reused include plastic lumber picnic tables, chairs, and displays. We’re regularly researching and testing even more reuses.

Since beginning in 2019, the TagBack logo has been printed on millions upon millions of ties and tags and customers and consumers have helped collect more than 180,000 pounds of returns by dropping in one of 75 U.S. drop box locations or mailing directly.

2. Plastic Reduction

Many industries are interested in solutions that offer a reduction in plastic packaging.

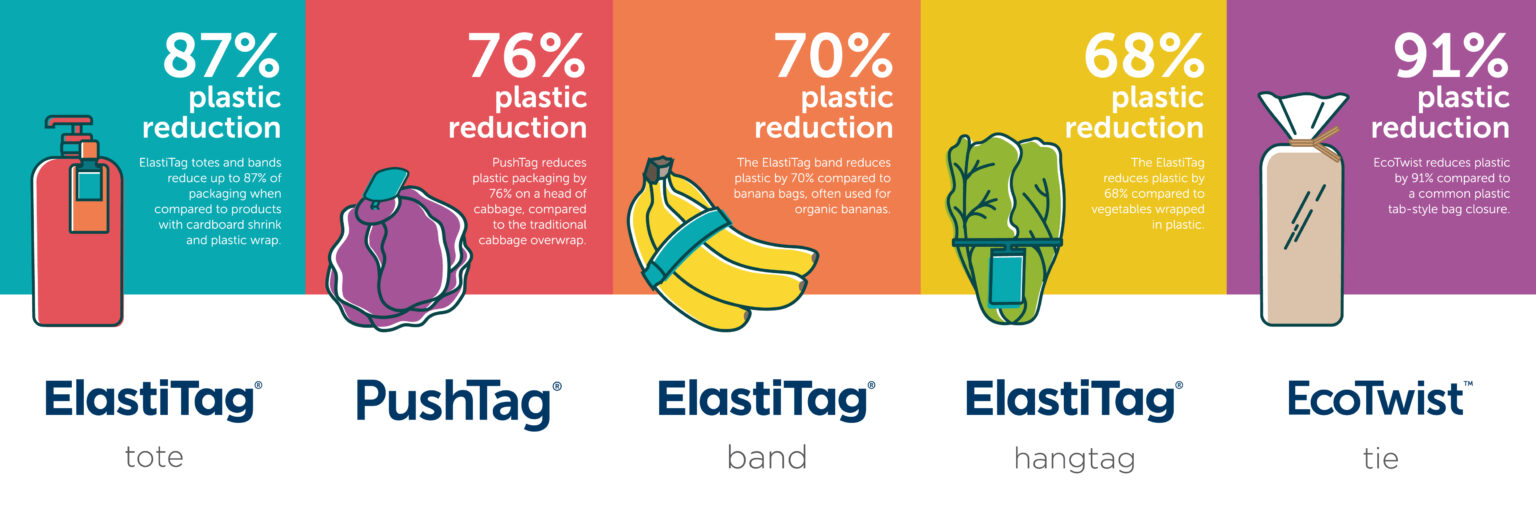

Bedford conducted a weight comparison between its packaging ties and tags and other common packaging alternatives like produce overwrap and clamshells. The study found that from many aisles across the department store, Bedford solutions offer a plastic packaging reduction between 68-91%, depending on which products are being compared.

3. Product Alternatives

We continuously explore how we can use more eco-friendly raw materials to create our packaging and bendable solutions.

Some of these options include:

EcoTwist

Our first twist tie spool made of recycled paper.

Our first twist tie spool made of recycled paper.

EcoTwist’s paper content is 100% recycled, at least 40% of which is post-consumer recycled paper. It can be used in various tie widths or put ups and runs on existing application equipment without any machine changes.

When compared to the standard 8,000 foot plastic/paper twist tie spool currently used by the baking industry, EcoTwist:

- Uses 18% less plastic

- Has 12% more material (9,000 feet) per spool, resulting in more uptime

- Gives a natural, sustainable appearance

The plastic reduction achieved by switching from a common plastic tab-style bakery closure is even greater, at upwards of 91%.

BioForm

Our metal-free, bendable face mask nose piece made of a proprietary blend of materials incorporating bio-based polymers. Since it is made without wire, BioForm is ideal for use in MRI machines and other medical procedures that require nonmetallic materials.

Our metal-free, bendable face mask nose piece made of a proprietary blend of materials incorporating bio-based polymers. Since it is made without wire, BioForm is ideal for use in MRI machines and other medical procedures that require nonmetallic materials.

BioForm is spooled for high-speed automation, no changeover required.

CloseIt Bio-Clip

One of the newer products to join Bedford’s produce packaging line is CloseIt Bio-Clip, a commercially-compostable bag closure commonly used on items like bagged potatoes or carrots that is comprised of 100% USDA certified biobased content. It was tested and received BPI Commercial and OK compost INDUSTRIAL certifications.

One of the newer products to join Bedford’s produce packaging line is CloseIt Bio-Clip, a commercially-compostable bag closure commonly used on items like bagged potatoes or carrots that is comprised of 100% USDA certified biobased content. It was tested and received BPI Commercial and OK compost INDUSTRIAL certifications.

It is compatible with existing application equipment.

4. Manufacturing Best Practices

Not only are we looking for more sustainable raw materials, we’re also continuously searching for ways to reduce our manufacturing footprint.

One of the ways in which we do this is by implementing closed-loop manufacturing lines, to eliminate and reuse production waste.

Thanks to a partnership with our energy supplier, we’re able to manufacture our solutions from carbon-free and renewable energy sources, like wind, solar, and water. The result is a 100% net-zero carbon power supply.

Sustainability Programs

Our in-house sustainability committee stays on top of new sustainability trends and innovations and new opportunities are regularly explored so that Bedford can offer a wide portfolio of packaging solutions.

For more on our sustainable practices, read our sustainability report.